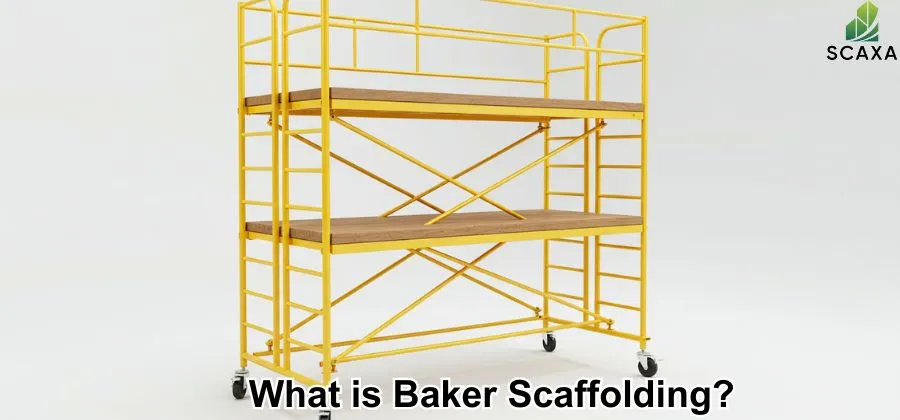

Baker scaffolding works by offering workers an elevated, stable platform supported between two end frames. They can adjust the height of the platform in 2 to 3-inch increments as per project requirements. The built-in ladder of the baker scaffold eliminates the need for climbing and lets workers ascend for safe internal access. Baker scaffolding can be stacked for greater elevation than 6 feet, which is a standard height.

The main advantages of baker scaffolding include its high load capacity (up to 1000 lbs), easy maneuverability in tight spaces, tool-free quick assembly, height-adjustable platform and mobility with locking caster wheels. Mainly, baker scaffolding is used for HVAC installation, cleaning of skylights and tall windows, interior painting, light construction tasks, installation and finishing of Drywall.

What is Baker Scaffolding?

Baker scaffolding is a versatile, lightweight working platform designed mainly for indoor use. It is a temporary structure that is designed with a modular framework featuring built-in ladders, locking caster wheels, and optional safety components. It is regarded as the best alternative to ladders for DIYers or professionals who are looking for a stable and secure platform for work. Backer scaffolding is compact, mobile, and adjustable compared to fixed scaffolding, and thereby, it is the most suitable temporary structure for tight indoor spaces and tasks that need frequent repositioning.

What are the Advantages of Baker Scaffolding?

The eight advantages of baker scaffolding are as follows:

- Compact and maneuverable (fits through doorways, tight spaces)

- Adjustable platform height

- Portable with locking caster wheels

- Easy and quick assembly

- High load capacity (up to 1,000 lbs)

- Versatile (can be used as rack, cart, or stand)

- Built-in safety features (guardrails, anti-slip platform)

- Stackable design for higher reach

1. Compact and Maneuverable

Baker scaffolds are compact and, thereby, easy to maneuver in tight indoor spaces and standard doorways. Their compact design makes them an ideal scaffolding to use indoors in commercial and residential spaces.

2 .Adjustable platform height

The height of the baker scaffolding is adjustable. Workers can work comfortably at different heights without any need to constantly move or install a scaffold. Whether workers need to perform ceiling work or require mid-wall access, they can make changes in height and complete the task easily. The platform is set at different intervals ranging from 18 inches to 6 feet.

3 .Portable with locking caster wheels

Baker scaffold is designed with caster wheels that make this temporary structure portable. Workers can easily move it around from one place to another. Wheels are designed with a locking mechanism that ensures that the unit stays securely in place and doesn’t accidentally move while workers are performing their tasks.

4. Easy and Quick Assembly

Baker staging doesn’t require technical expertise or tools for assembly. Therefore, DIYers usually rely on this scaffold as it’s the best alternative to a ladder. Quick and simple assembly saves time on the job site and lets workers focus on the work at hand instead of setting up or taking down the whole framework again and again.

5. High Load Capacity

The load capacity of the baker scaffolding platform is up to 1000 lbs. This high load capacity makes it quite a useful temporary structure to use for tasks where multiple workers need to work at the site while keeping their heavy tools and equipment on the platform.

6. Versatility

Baker scaffold is a versatile temporary structure. When it is not being used as a work platform, it can be turned into rolling stands, carts or racks. The flexible design and multi-functionality of baker staging make it useful for different applications and industries.

7 .Built-in Safety Features

Baker scaffolding has built-in safety features such as anti-slip platforms, guardrails, and toe boards. These safety features let workers work at elevated platforms with minimal risk of falls or accidents and knowing that they are secure.

8. Stackable design

Baker scaffolding is stackable. This means that multiple units of scaffolding can be stacked vertically to achieve higher reach without any compromise on safety and stability. The height limit for a single unit of baker scaffold is 6 feet, which is a standard height. But when your project requires more height than that, another unit can be stacked vertically. The stacking option is more cost-effective than renting tall towers for your work.

What are the disadvantages of Baker Scaffolding?

The seven disadvantages of baker scaffolding are as follows:

- Risk of tipping due to narrow base

- Fall hazards if misused (e.g., no guardrails, improper climbing)

- Limited height without add-ons

- Unsuitable for outdoor use (wind, uneven ground)

- Mobility risks (wheels can catch on debris)

- Electrical hazards if used near power lines

- Requires proper assembly and regular maintenance

1. Risk of tipping due to narrow base

The major risk with the baker scaffold is tipping due to the narrow base. The compact structure of baker staging makes it more susceptible to instability, especially when workers are doing jobs on uneven surfaces and at higher elevations. The best way to prevent the risk of tipping due to a narrow base is to follow the manufacturer’s guidelines about base extensions and height limits.

2.Fall hazards if misused

Baker scaffolds may lead to fall hazards if misused. Many times, workers climb on the frame instead of using its built-in ladder, and this climbing leads to fall accidents. Another scenario is when guardrails or toeboards are not installed on the baker scaffold. Ignoring these essential safety features while working in elevated areas can cause serious accidents. Project managers often overlook or underestimate the importance of fall protection for baker scaffolding as it is mostly used indoors. However, these safety measures are essential, especially when working on a busy job site.

3.Limited height without add-ons

Baker scaffolding has height restrictions without add-ons. The standard height is 6 feet. When additional units are stacked, the height limit can be extended. A single unit is unsuitable for large construction projects or getting access to high-ceiling spaces unless managers are ready to spend more money on its add-ons. Another risk associated with improper stacking is that it always compromises stability and puts workers at risk.

4.Unsuitable for outdoor use

Baker staging is designed to complete tasks indoors. It is not suitable for outdoor use because heavy wind may cause the structure to sway. It has built-in caster wheels that are useful only on flat surfaces and lead to mobility risks on uneven ground. The baker scaffold may make an unexpected shift when it comes in contact with sloped terrain or debris-laden areas. When wheels get stuck in debris, they may stop working suddenly, or the title, either way, is a hazard.

5.Electrical Hazards

The most overlooked risk of baker scaffolding is the electrical one. The frame of the baker scaffold is made of metal that is hazardous to use near light power lines or electrical installations. Accidental contact with it leads to electrocution, especially when workers are doing their tasks in an industrial area. Workers know how to identify electrical hazards and take necessary precautions to avoid safety risks.

6.Requires Proper Setup and Regular maintenance

Assembly of baker scaffolding is pretty simple, yet its complete setup needs to be done carefully. Besides, it requires regular maintenance. The use of worn-out caster locks, rusted joints, or misaligned components puts workers at risk. There is a need to regularly inspect every part of the scaffold and fix the issues, and this maintenance is time-consuming.

What are the uses of Baker Scaffolding?

The twelve common uses of baker scaffolding are as follows:

- Interior painting and decorating

- Drywall installation and finishing

- Electrical and HVAC installation

- Maintenance and repair work

- Window and skylight cleaning

- Light construction tasks

- Working on stairways or uneven surfaces

- Multi-purpose use (e.g., miter saw stand, storage rack)

- Ideal for tight indoor spaces

- Easy relocation on job sites

- Adjustable for different ceiling heights

- Stackable for higher access

1.Interior Painting and Decorating

Baker scaffolding provides a wide, stable platform where workers can stand and move around easily to paint the walls and ceilings. Baker scaffolding makes it easy for them to perform their task safely and without relying on a ladder that requires frequent repositioning. Since the height of the baker scaffolding is super adjustable, you can read the varied levels of the ceiling effortlessly. When workers need to do painting and interior decorating in a space with complex architectural designs, the baker scaffold provides easy access to these otherwise difficult-to-reach spots.

2.Drywall installation and finishing

Baker scaffolding is quite useful for professionals who need to work at an elevated level for mudding, taping and sanding drywall. This temporary framework offers them a safe and stable ground to continue their work of drywall installation and finishing. This option is far better than a ladder, which often causes fatigue. The platform of the baker scaffold offers generous surface access where workers can stand without getting unstable and then get easy access to tools and materials. This easy access and stable working platform help them complete their task efficiently.

3. Electrical and HVAC Installation

When it comes to the installation of ductwork, wiring systems in the ceiling, and some lighting fixtures, HVAC and electrical professionals make the most of Baker scaffolding. This temporary structure has built-in caster wheels that allow workers to enjoy effortless movement across rooms and hallways. They can use the locking mechanism of wheels to keep the baker scaffold securely in place when they are working on their tasks.

4.Maintenance and Repair Work

Baker scaffolding is commonly used for maintenance and repair tasks in both commercial and residential settings. Workers rely on this platform when it comes to HVAC servicing, wall [atching, plumbing adjustments, replacement of lighting fixtures and ceiling repair. It’s easy to adjust platform height to access high ceilings, utility lines and ductwork. It eliminates the need for ladders that offer limited space and has an associated risk of instability. Lockable caster wheels let workers move scaffolds from one place to another without breaking down the unit. Its mobility feature makes it an ideal temporary structure to use for repair and maintenance tasks in office spaces, hospitals and schools where workers need to access multiple maintenance points as quickly as they can

5.Window and Skylight Cleaning

When it comes to cleaning interior windows and skylights in malls, atriums, commercial lobbies and stairwells, nothing proves as useful as a baker scaffold. This temporary structure offers stable elevation and easy access to difficult-to-reach areas. The reason workers prefer baker scaffolding for such tasks is because of its ability to fit in a narrow or tight indoor area such as a built-in structure or corridors. Its smooth platform lets workers get close access to large and high window panes, especially skylights. They can maintain their balance on the platform while using both hands for cleaning purposes. The anti-slip surface of the platform reduces the risk of slipping when cleaners are using water or cleaning solutions. The portable design lets cleaners move scaffolding easily along the window line instead of clumping up and down, so their cleaning time is reduced to a great extent.

6.Light Construction Tasks

Baker scaffolding is a perfect access platform for light construction tasks such as the installation of crown moulding, ceiling tiles, acoustic panels, light frames, wall panels, baseboards, and fixtures. This type of scaffolding provides a stable platform where workers can move, kneel or use tools freely. The ladder usually limits movement and tool access, but the scaffolding platform has a 1000 lb load capacity so workers can keep their power tools and materials nearby. Since the height of the platform is adjustable, it’s easy for workers to move the platform at the desired elevation with ceilings and wall lines. This adjustment is quite important when workers need to perform critical construction tasks such as measuring, drilling or aligning finishing trims. When project managers have tasks of office renovation or retail build-out, they use baker scaffolding as it allows workers to complete tasks quickly and without any damage to the surroundings.

7.Working on Stairways or Uneven Surfaces

Baker scaffolding is also used to work on stairways and uneven surfaces. When additional parts, such as stairway kits or adjustable leg extensions, become part of the overall framework, then this scaffolding can be set up on sloped or irregular surfaces. One side of the scaffold can be raised or lowered, letting workers complete their task on a level working platform, even on stairs or ramps. Usually, leg extensions or stairway kits are used alongside baker staging when workers need to complete some stairway-related tasks such as repairing ceiling areas, lighting installation above staircases and painting stairway walls. Adjustable legs of the framework are locked and provide a stable platform for workers, even on inclined surfaces.

8.Multi-Purpose Use (e.g., Miter Saw Stand, Storage Rack)

When you are not using scaffolding, you can use baker unit creative for many different purposes. For example, it serves as a mitre saw stand that you can use for wood cutting. It can be your mobile tool rack for keeping all the essential tools in one place. You can turn the baker scaffold into a temporary storage shelf where you can keep power tools, paint cants and drywall sheets. Whether you keep it in your workshop garage or job trailers, its adaptable design reduces the need for additional carts or tables. The multi-functional design of the baker scaffold makes it a cost-effective investment. You can organize a site efficiently by using a baker scaffold as your mobile workstation or tool bench.

9.Ideal for Tight Indoor Spaces

Baker scaffolding is ideal to use in tight indoor spaces where traditionally large or fixed systems seem impractical. Compact frames of this temporary structure fit through a stand doorway and offer excellent maneuverability in tight spaces. The narrow width and modular design let you set this temporary structure in spaces where the ladder easily becomes unstable and where you can’t use a fixed scaffold. Once you are done working in a tight space, simply roll it out through doors- no need to disassemble the whole framework.

10. Easy Relocation on Job Sites

Baker scaffold has built-in swivel caster wheels that let workers move this temporary structure all across job sites without any disassembly and fatigue. It becomes useful in commercial, school and industrial plant projects where frequent relocation is required. Workers can easily push the scaffold without breaking it down. It will reduce project downtime and physical strain. Easy relocation on the job site maintains consistency and momentum of a project. Baker scaffold is an ideal temporary structure to use for multi-room projects and a fast-paced environment based on its easy maneuverability.

11.Adjustable for Different Ceiling Heights

Baker scaffold is featured with a height-adjustable platform where workers can change the height with a 2-inch increment. The platform can be raised or lowered without using any tools. This adjustability lets workers set the platform at the most ergonomic height and complete their tasks conveniently. Ceiling heights usually vary across buildings. This change is a big challenge for workers who need to access upper areas safely. Fortunately, when workers rely on baker scaffolds, they can change recessed lighting in a 10-foot ceiling or repair drywall on a 7-foot drop ceiling. Baker staging offers them optimal level access without awkward overextensions, so it reduces fatigue and back strain for workers and lets them complete painting, wiring, and fixture installation work easily.

12.Stackable for Higher Access

Baker scaffolding is stackable, meaning multiple units of temporary structure can be connected to extend vertical reach. When workers need to work on high ceilings, tall windows and indoor atriums, they often need to go beyond the standard 6-feet height. In that scenario, they can handle high-access tasks through a stackable baker scaffolding, which eliminates the need to spend more money on large and expensive access systems. When stacking a baker scaffold, project managers follow safety guidelines and add safety ladders, outriggers and guardrails to the overall framework. The ultimate purpose of adding these safety features is to let workers work safely at 12 feet or higher.

What are the Parts for Baker Scaffolding?

The five essential parts of Baker Scaffoldings are as follows:

- End Frames with Built-in Ladders

- Plywood Platform (with or without Trapdoor)

- Side Braces or Trusses

- Locking Caster Wheels

- Locking Pins or U-Shaped Pins

1. End Frames with Built-in Ladders

End frames are vertical sides of the scaffolding tower and work as a primary connection point for platforms and braces. They are made of aluminium or welded steel and usually have integrated ladders. The end frames create the core framework of the scaffold and provide support to the platform between them. They come with built-in ladders that let workers safely ascend inside the unit. There is no need to climb the exterior to access the platform. As a result, these end frames minimize fall risks.

2. Plywood Platform (with or without Trapdoor)

A flat and strong panel made of reinforced plywood with steel edges. It acts as a working surface in a baker’s scaffolding. The platform of baker scaffolding is a place where workers stand and put their tools and materials. Usually, the platform has an anti-slip surface to reduce accidental slipping and maintain worker safety. The Platform may come with trap doors or hatches that let workers climb through a stacked scaffold. A premium-quality platform can support loads up to 1,000 lbs.

3. Side Braces or Trusses

Side braces or trusses are horizontal or diagonal support bars connected with the end frame. They provide lateral stability to baker scaffold structure and maintain structural integrity. Braces lock the frame together and prevent it from collapsing and swaying under load and against lateral forces. Beaches are either straight or come in an X-shape, depending on the model of the baker scaffold. Locking pins makes the installation of side braces and trusses super simple in terms of overall structure.

4. Locking Caster Wheels

Locking caster wheels are swivelling wheels attached to the base of the baker scaffold. They are made of either rubber or polyurethane. These wheels are designed with built-in locking mechanisms to prevent accidental movements. Baker scaffolding can be rolled around job sites easily because of caster wheels.

5. Locking Pins or U-Shaped Pins

Locking pins are steel fasteners used to secure joints and connections between different parts, such as side braces, frames and platforms. Locking pins are inserted through frame holes to connect components securely and prevent accidental disassembly and slippage. U-shaped pins make assembly tools free and quick. They are required to maintain the safety and stability of the overall framework.

Optional & Add-On Components

The six optional & add-on components of baker scaffolding are as follows

- Guardrail Systems

- Outriggers

- Adjustable Leg Extensions

- Platform Extensions

- Tool & Storage Shelves

- Motorized Climb-N-Go System

1.Guardrail Systems

Guardrail systems are safety rails attached at the top of the scaffold to prevent falls. This system comprises side rails, end rails and toeboards that enclose the working platform. As per OSHA guidelines, scaffolds must be equipped with guardrail systems when working at height, as these systems provide fall protection. It is mandatory to use guardrail systems near edges when baker scaffolds are stacked.

2. Outriggers

Outriggers are extendable stabilizer arms connected to the scaffold’s base to increase the footprint. They widen the base area and reduce the risk of tipping while boosting stability. Whenever baker scaffolds are stacked, outriggers are used in high-traffic areas. Some outrigger models have adjustable feet for levelling scaffolding on uneven terrain.

3. Adjustable Leg Extensions

Adjustable leg extensions are height-adjustable legs attached to the base to accommodate uneven surfaces. Baker scaffolding must have leg extensions when workers need to work on irregular floors, sloped surfaces or stairs. Each leg is adjusted to the level of the platform while offering workers comfortable reach and safety.

4. Platform Extensions

Platform extensions are add-on pieces that extend the width or the length of the working platform. Whenever workers need more room to store tools or maneuverability, platform extension comes in handy. Extensions accommodate multiple people on the same platform. They prove useful parts of baker scaffolding when a project requires broader coverage, such as mural painting or ceiling tile replacement.

5. Tool & Storage Shelves

Tool and storage shelves are shelving units mounted to a frame of scaffold for holding hardware, supplies or tools. These shelves keep the work area and workers organized. Tools are within arm’s reach of workers. Shelves are removable and portable. Workers can keep lightweight power tools, brushes, taps or small bins of screws on these shelves.

6. Motorized Climb-N-Go System

A motorized climb-n-go system is a battery-powered drive system attached to the wheels for motorized movement. This system lets workers move the scaffold without pushing or disassembling it. This system reduces labour fatigue and increases productivity in large indoor spaces such as auditoriums, gyms and warehouses.

What is the Safety Checklist for Baker Scaffolding?

- The safety checklist for baker scaffolding include:

- Pre-use Inspection

- Assembly and setup

- Usage guidelines

- Hazard awareness

- Maintenance and storage

Pre-Use Inspection

It is important that a competent person oversees the assembly of the baker scaffold and performs daily inspections before, during and after use. The inspector must use dated inspection tags on the working site. Every component of the scaffold needs to be inspected for damage, defect or wear. Replacement of compromise is important before use. The inspector must verify that the platform is fully planked and has no gaps greater than one inch. The platform must be clean and free from slippery substances. When the baker scaffold is stacked, it is important to confirm that guardrails and toeboards are installed on the sides and ends of the platform to prevent falls.

Assembly and Setup

Baker scaffold must be installed on a firm and level surface. Make sure that all braces are attached securely and the scaffold surface is square and plumb. Lock all caster wheels to prevent movement during use. Always install outriggers when stacking baker scaffolding units at a height above 6 feet.

Usage Guidelines

Do not climb on cross braces; always use a built-in ladder to access the platform of a baker’s scaffolding. Never move the scaffold while occupied. Workers should descend while relocating a scaffold. Do not exceed the load limit specified by the manufacturer. On average, the load capacity of a baker scaffolding platform is 1000 lbs, and it includes the weight of workers, materials and tools. When installation of a guardrail is not feasible, always use a personal fall arrest system.

Hazard Awareness

Maintain a safe distance from electrical equipment and powerlines. Do not use baker scaffolding in heavy wind, rain or adverse weather conditions. Always keep the scaffold clean and clear all the obstructions and debris when moving the mobile baker scaffolds around to prevent tipping.

Maintenance and Storage

Perform routine maintenance checks on all the components to ensure that they are working in good condition. Store scaffold components properly. Always keep a full record of inspections, incidents, repairs and maintenance.

How much is the rental of Baker Scaffolding in UAE?

The rental cost of Baker scaffolding depends on four factors: rental duration, location, additional services, and scaffolding specifications.

Rental duration: The longer you rent a baker scaffold, the lower the rent you will pay. It means that you can expect discounted rates for a long rental period.

Location: The rental cost of Baker scaffolding in the UAE varies from one location to another. For example, you pay a different price for renting a baker’s scaffold in Sharjah than in Dubai.

Additional Services: The rental cost of the baker scaffolding increases when you ask for additional services like installation or delivery.

Scaffolding Specifications: The rental cost of a baker scaffold also depends on the specifications you provide. The scaffolding’s size, height, and load capacity can affect the rental price.

What are the OSHO Guidelines for Baker Scaffolding?

The OSHA guidelines for baker scaffolding are as follows:

- Follow the manufacturer’s written instructions for baker scaffolding use, setup and dismantling.

- Provide additional bracing when height exceeds three times its smaller base dimensions.

- Always provide a personal fall arrest system to an employee working more than 10 feet above a lower level.

- Use outriggers when erecting multi-level Baker scaffolding or when the work platform exceeds certain heights.

- Supervise and train all workers using the Baker scaffold.

- Provide safe work procedures based on the type of work to be performed.

- Keep the platform free from tripping hazards.

- Ensure the scaffold is on a suitable and stable ground.

- Stay at least 10 feet away from energized power lines.

What is the Maximum Height for Baker Scaffolding?

The maximum height of the baker scaffold is 6 feet for basic configuration. This height can be increased by stacking additional frames vertically… Standard scaffolding has a 10-foot threshold for fall protection. Baker scaffold has high tip-over potential due to its narrow base. The use of outrigger systems and railing kits, along with height addition, is mandatory to maintain stability and safety factors.

What are the dimensions of Baker Scaffolding?

The dimensions of the baker scaffolding platform are 6 feet long by 30 inches wide. The height of the working platform can be adjusted in increments, usually 4 inches, and ranges from 5 to 6 feet in a single frame. The load capacity of the working platform is up to 1000 lbs. Multiple frames are stacked vertically to increase the working height of the baker scaffold.