Portable scaffolding works by putting together its modular end frame with adjustable platforms and cross braces. Its lockable caster wheels at the base offer easy maneuverability and effortless movement. Its optional components, such as screw jacks or outriggers, stabilize the overall portable scaffold on uneven terrain. Once the wheels of the scaffold are locked, this scaffold offers a safe, elevated platform where workers can stand comfortably and complete their tasks. Portable scaffolding is mainly used for painting and decorating, plastering and drywall installation, electrical and HVAC work, maintenance and repairs, and event setup and management.

What is Portable Scaffolding?

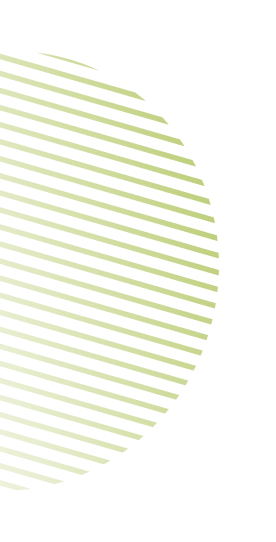

Portable scaffolding is a lightweight, movable scaffolding system that lets workers access difficult-to-reach areas at elevated levels in construction, maintenance, and installation projects. Unlike fixed scaffolding that can’t be repositioned easily, portable scaffolding makes frequent repositioning a hassle-free experience for workers. They can move it around without complete disassembly. The main components of portable scaffolds include metal frames, platforms, casters (wheels), and safety features like guardrails and toeboards. The main benefits of portable scaffolding are enhanced mobility, time and labour efficiency, versatility, improved safety, and cost-effectiveness.

What are the Benefits of Portable Scaffolding?

The seven benefits of portable scaffolding are as follows.

- Enhanced mobility

- Time and labor efficiency

- Versatility

- Space-saving design

- improved safety

- Cost-effectiveness

- Accessibility.

1. Enhanced Mobility

Enhanced mobility is ensured with portable scaffolding and the integration of wheels or casters. Workers can move scaffolds all across the work site effortlessly. There is no need to assemble or dismantle the whole system over and over again. As a result, its setup time is reduced, and workers enjoy great coverage. The enhanced mobility of the portable scaffold makes it an ideal temporary structure to use for large projects, especially those that require frequent repositioning.

2. Time and Labor Efficiency

When compared with traditional scaffolding, portable scaffolding has an edge in terms of reducing labour energy and saving time. More workers are required to set up traditional scaffolds, while portable scaffolds don’t need more workers. The setup of a portable scaffold is pretty quick, and workers spend less time on assembly and more time on the task at hand. Projects are completed at a fast pace, and managers spend less money on labour.

3. Versatility

Portable scaffolds are versatile and can be used for a wide variety of tasks such as general maintenance, painting, ceiling installations, etc. Whether it’s an indoor project or an outdoor one, workers can adjust the height of the scaffold and make it themselves as per their work environment and project requirements.

4. Space-Saving Design

Portable scaffolds are more compact than traditional scaffolds, are less bulky, and cover more ground space. Portable scaffolding is available in foldable or collapsible styles, so it takes up less space and proves useful for small job sites. The space-saving design of the portable scaffold makes it easy for contractors to take this temporary structure to a place with limited space and get the job done.

5. Improved Safety

Advanced portable scaffolds are integrated with a wide variety of safety features, such as secure ladders, anti-slip platforms, toeboards, guardrails, and lockable wheels. These features make this temporary structure safe and secure to use and reduce the risk of falls at the workplace when used in the right way.

6. Cost-Effectiveness

Investment in a portable scaffold offers the best value for the money, as managers can use the same scaffold for multiple projects. There is no need to pay ongoing rental costs or investment in parts replacements. The portable scaffold is reusable and has sturdy construction. It reduces labour hours as the assembly is super simple, and it also reduces transportation costs due to its space-saving design. Project managers can expect a good return on investment whenever they propose a mobile scaffold.

7. Accessibility

Portable scaffolding features include height adjustment and easy maneuverability. Workers can access hard-to-reach areas through this moving scaffold; they no longer need to rely on complex rigging or ladders. The portable scaffold is an ideal temporary structure in confined or regular spaces, as project managers can’t install traditional scaffolds in such spots.

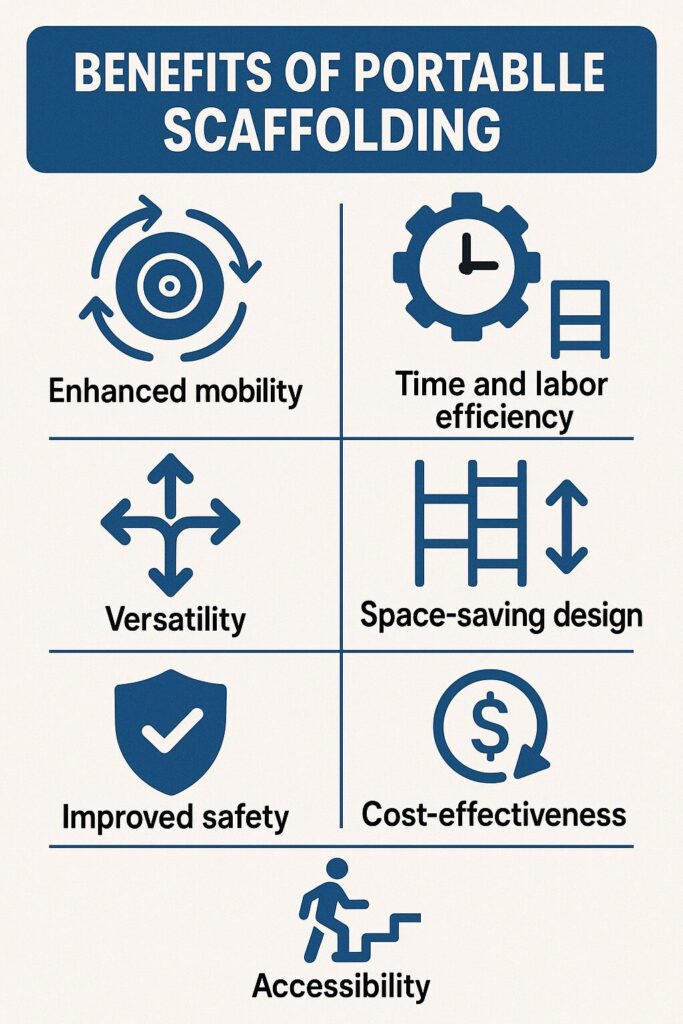

What are the Disadvantages of Portable Scaffolding?

The six disadvantages of portable scaffolding are as follows:

- Stability concerns

- Limited load capacity

- Safety hazards

- Terrain and weather limitations

- Storage and Transportation Challenge

- Training requirements.

1. Stability Concerns

A portable scaffold has a stability concern, especially when used at height or on uneven surfaces. The whole structure may shift or tip when the wheels are not locked. It provides good support for light-duty tasks. But it can’t be used for heavy-duty tasks and as a stationary support for a long period.

2. Limited Load Capacity

Portable scaffolding has low weight tolerance, so it is not designed to support heavy tools, large materials, or multiple workers. Fixed scaffolds, on the other hand, are heavy-duty scaffolding systems and are known for their excellent load-bearing capacity. Overloading a portable scaffold leads to accidents at the workplace, such as structural collapse or failure.

3. Safety Hazards

Portable scaffolding is associated with different safety hazards such as fall accidents, slip and trip, and structural collapse. When a structure is not set up properly, it leads to accidents. When workers forget to lock their wheels then, it leads to falls and slip accidents. There is a need to use fall protection on this system, lock the wheels, and do proper weight distribution when setting up the system on uneven ground; these are the best ways to prevent hazards.

4. Terrain and Weather Limitations

Portable scaffolds are designed to be used on a flat and stable surface. They don’t perform well on uneven ground, sloped areas, mud, or gravel; this terrain compromises overall safety and mobility and puts workers at safety risks. Outdoor weather settings such as heavy rain, strong winds or extreme ice make portable scaffolding dangerous because it reduces the stability and traction of the overall system.

5. Storage and Transportation Challenges

Small systems are portable and take up less space. However, bulky and heavy models with multiple sections are difficult to transport. They take up huge cargo space and require protective storage to prevent damage during transit. The storage and transport of heavy and bulky structures becomes quite challenging for project managers.

6. Training Requirements

Although the overall structure of the mobile scaffold is simple, workers need to go through a process to use. Workers need to familiarize themselves with load limits, locking mechanisms, proper setup, and safe usage practices during training. When training is insufficient, the risk of workplace injuries increases.

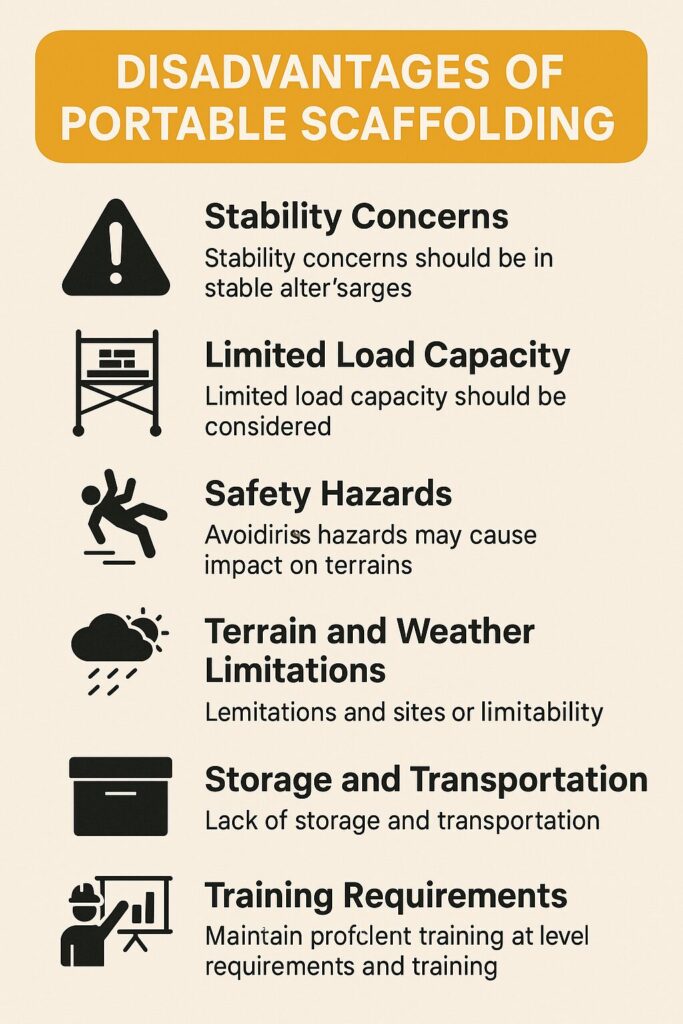

What are the uses of Portable Scaffolding?

The eight uses of portable scaffolding are as follows:

- Painting and decorating

- Plastering and drywall installation

- Electrical and HVAC work

- Construction and renovation

- Maintenance and repairs

- Event setup and management

- DIY projects

- Industrial applications.

1. Painting and Decorating

Portable scaffolds make painting easy for painters, who can move the scaffold all around and complete their interior and exterior painting jobs. This scaffold provides a stable and wide standing surface for painters who can effortlessly do the tasks of tapping, wallpapering and trimming with this structure.

2. Plastering and Drywall Installation

When it comes to the installation of drywall and plastering, workers need easy access to the highest areas of walls and ceilings for a long period of time. Portable scaffolding allows installers to get easy access. They can stand on a secure working platform, keep the required materials on it, and perform their tasks efficiently.

3. Electrical and HVAC Work

HVAC workers and electricians use the portable scaffold. When it comes to installing and servicing ductwork, wires, and ceiling lights, these structures make all such tasks simple for professionals to handle. They can adjust and reposition scaffolds, cover large areas of commercial buildings and manage multi-room projects.

4. Construction and Renovation

Construction and renovation tasks require workers to access difficult-to-reach or tight spaces that have vaulted ceilings, stairwells, etc. In this scenario, portable scaffolds prove useful as workers can use them to perform various tasks such as ceiling tile installation, framing, and insulation.

5. Maintenance and Repairs

The portable scaffold is used for routine repair and maintenance tasks in commercial, residential and industrial spaces. Workers set up moving scaffolds and perform different tasks such as gutter cleaning, fixing ceiling leaks, light fixture replacement and siding repair. A mobile scaffold offers them a secure elevated workspace that they can use to perform such tasks with ease.

6. Event Setup and Management

Portable scaffolding is highly mobile, and thus, it allows workers at event sites to set up stage backdrops, lighting rigs, sound systems, signage, and decoration. Events can quickly assemble portable scaffolds and then move them all around to cover large venues, convention centres, concert spots, and stadiums.

7. DIY Projects

Homeowners and hobbyists use portable scaffolding for various DIY projects. A portable scaffold is a safe and more convenient alternative to ladders for them. They can paint a stairwell, clean roof gutters, install ceiling fans, clean ceiling fans and repair rooflines by using a rolling scaffold. Height adjustment features make it a valuable tool that homeowners can use to perform home renovation, repair and cleaning tasks effortlessly.

8. Industrial Applications

When it comes to equipment servicing, infrastructure inspection, machine repair, and overhead maintenance in industrial facilities, warehouses, and processing facilities, portable scaffolding is widely used. This mobile structure can be moved all around tight spaces and also around machinery. It’s a practical solution to reach elevated areas in an environment where fixed or permanent scaffolding is impractical.

What are the Parts of Portable Scaffolding?

The ten parts of the portable scaffolding are as follows:

- Base plates and casters

- End frames

- Cross braces and Horizontal braces

- Platforms

- Guardrails and toeboards

- Outriggers

- Adjustable screw jacks

- Coupling pins and spring clips

- Ladders for stairways

- Optional accessories

1. Base Plates and Casters

Base plates are flat metal plates that are located at the bottom of scaffold legs. Their main function is to enhance the overall stability of the structure while distributing weight evenly. Casters are heavy-duty swivelling wheels that have locking mechanisms. They are attached to a portable scaffold’s frame to provide mobility features. Casters allow easy movement of the overall structure at the workplace. The locking mechanism of casters keeps the structure in place while workers are using platforms for some tasks.

2. End Frames

End frames are vertical structural parts of portable scaffolding. They are located at each end of the scaffolding units. End frames provide the main structural support. They are usually part of built-in ladder rungs. End frames are lightweight yet sturdy and make assembly simple and quick.

3. Cross Braces and Horizontal Braces

Cross braces are diagonal metal bars that create an X-shape between scaffold frames. Horizontal braces are metal bars that run parallel to the platform. Braces are used in portable scaffolding to stabilize the structure and protect it against lateral movements. Cross braces and horizontal braces are designed with easy locking and unlocking mechanisms in portable scaffolding so workers can set up and break down the system without compromising its structural integrity.

4. Platforms

Platforms are flat surfaces installed between the end frames to offer a workspace area to workers. In a portable scaffold, aluminium, plywood or steel-made platforms are used with anti-slip coatings. The platform is lightweight, and workers can adjust its height per project requirements.

5. Guardrails and Toeboards

In portable scaffolding, guardrails are safety rails installed alongside the top edges of the scaffold to prevent fall accidents. Toeboards are barriers installed at the base of the platform’s edges to prevent materials and tools from falling off. When working at height, it is important to install guardrails and toeboards to maintain workplace safety.

6. Outriggers

Outriggers are horizontal extensions at the base of portable scaffolds. They are used to provide additional stability to the structure while raising its footprints. Outriggers are important parts of portable scaffolds when working at greater heights. In portable systems, outriggers are detachable and adjustable, so letter workers customize scaffold stability according to working conditions. It’s mandatory to use outriggers when casters are used on narrow or tall scaffolds.

7. Adjustable Screw Jacks

Adjustable screw jacks are vertical adjustment mechanisms at the base of the scaffold. They allow workers to adjust the height of the portable scaffold and level the structure on uneven surfaces. Screw jacks enhance overall structure safety as they make sure that scaffold sits evenly on the ground and it prevents the risk of structure collapse or wobbling.

8. Coupling Pins and Spring Clips

Coupling pints are metal connectors that align scaffold frames on top of one another. Spring clips or locking pins are secure frames, platforms and braces in place. Coupling pins and spring clips are used during the setup of portable scaffolding. Coupling pins make vertical stacking safe, while spring clips maintain structural integrity through their locking functionality. Thanks to coupling pins and spring clips, workers enjoy the tool-free assembly of scaffolds at the workplace.

9. Ladders for Stairways

Ladders are integrated or attachable stairways that let workers enjoy safe access to elevated work platforms. In a portable scaffold, frames have built-in ladder rugs where external ladders or stair systems are added. This addition ensures safe combing and descent for workers who carry tools and materials.

10. Optional Accessories

Optional accessories for portable scaffolding include tool trays, platform extensions, weather-resistant covers, debris nets and material hooks. Tools trays or baskets are places where workers keep their tools so that they can easily reach them as and when required. Platform extensions expand the working platform. Weather covers, or canopies, are used to protect workers from weather conditions such as sun or rain. Debris nets are used on renovation and demolition sites to improve overall workplace safety.

What are the safety requirements of Portable Scaffolding?

The ten safety requirements of portable scaffolding are as follows:

- Load capacity

- Platforms

- Guardrails and toeboards

- Access

- Wheel locks

- Height restrictions

- Bracing

- Movement rules

- Inspection

- Training.

1. Load Capacity

Every portable scaffold has a load capacity that includes the weight of workers, tools and materials. Never exceed the manufacturer’s rated load capacity because overloading causes a system to become unstable or collapse, especially when it’s in motion or installed on an uneven surface.

2. Platforms

The platform must be fully planked or decked. It must have slip-resistant features. On a portable scaffold, the platform must be secured and centered on preventing sudden shifts during movement. Gaps between planks must be minimized to prevent tripping hazards.

3. Guardrails and Toeboards

Guardrails and toeboards must be installed on all sides of the platform when working at a height above 10 feet. When the height of the platform exceeds the safety threshold, then fall protection must be used.

4. Access

Portable scaffolds must provide safe, built-in access to ladders, stairways, and ladder rungs. Workers must not climb on scaffold frames and always use ladders for safe access. The ladder-style end frame must be clean and not have any obstruction.

5. Wheel Locks

All wheels must be locked before climbing a portable scaffold and while working on the platform. If the wheels are not locked, slight movement will cause balance loss and tipping. Forgetting or neglecting to lock the wheels before accessing the platform will put the lives of workers at risk.

6. Height Restrictions

On a portable scaffold, the height-to-base ratio should be 3:1 unless the structure is fully sacred and integrated with outriggers. Increasing the height of the structure without widening the base causes the structure to become insatiable. Besides, every manufacturer provides a height limit for the portable scaffold. Exceeding this limit without using an outrigger increases safety hazards.

7. Bracing

Cross braces and horizontal braces must be installed based on the design provided by the manufacturer. Bracing keeps the structure in its place and prevents structural collapse and sway. Portable scaffolding is a modular system, and missing one brace makes the structure unstable. It’s important to check that all the braces are put in the right places.

8. Movement Rules

Do not move portable scaffolds while workers or materials are on the platform. Slight movement, in this case, is caused by clause dislodgement of parts and tipping. Before repositioning a portable scaffold, always unload all the material and workers must descend.

9. Inspection

The portable scaffold must be inspected before each set and after making any adjustments or movement. Regular inspection checks let inspectors identify damaged casters, missing pins and loose connections. Portable units are prone to damage or wear due to frequent adjustment or movement. Therefore, frequent inspection is an important precaution to prevent safety risks.

10. Training

Every worker on the portable scaffold must be fully trained in safe assembly, disassembly, use, and movement of the overall structure. This modular system is quick to assemble, and workers may overlook its locking mechanism or weight limits. Training ensures that workers are familiar with critical safety steps.

What are the OSHA Guidelines for Portable Scaffolding

Following are the OSHA guidelines for portable scaffolding:

1. A qualified Person Must design a Scaffold

A qualified person must design and approve portable scaffolding. This person must ensure that the scaffold can support their intended loads and function safely.

2. Scaffolds Must Be Erected and Dismantled Under Supervision

Portable scaffolding must be erected and dismantled by trained personnel under the direction of a competent person- who can pinpoint existing hazards.

3. Fall Protection Required at Lower Heights for Portable Scaffolds

Fixed scaffolding requires fall protection over 10 feet of platform. However, portable scaffolds require a fall protection system at lower heights. Personal fall arrest systems (PFAS) may be required, especially when it’s impractical to install guardrails.

4. Casters Must Support the Intended Load Without Failure

OSHA specifies that wheels or casters must support the intended load four times without any failure. All wheels must be locked during use and have a proper locking mechanism.

5. The Scaffold Must Not Be Moved When in Use

OSHA strictly prohibits the movement of scaffolds when unsecured materials or workers are on the platform. Minor movement without unloading the scaffold is a violation of the safety guidelines by OSHA.

6. Maintenance of Manufacturer Labels and Manuals

OSHA requires that all portable scaffolds must retain manufacturer identification labels, manuals, and specification decals to be OSHA-compliant. These documents are used during inspection, setup and use and must be available on the work site.

How much is the rental for Portable Scaffolding?

The rental cost of portable scaffolding in Dubai is 100 to 300 AED per day for a standard aluminium mobile tower and 500 to 1000 AED per week for a mobile scaffolding, depending on its height or accessories. Contractors pay 1500 to 3000 AED per month on average for renting portable scaffolding in Dubai. The overall cost of portable scaffolding is based on five factors such as scaffolding type, height/size, accessories, rental duration, and service additions:

- Scaffolding type and Material: Aluminum scaffolds are used for indoor tasks as they are lightweight. Steel scaffolds are heavier and used for demanding projects. The cost of a steel scaffold is more than that of an aluminium one.

- Height/Size: A taller scaffold with large platforms cost more than small ones.

- Accessories: Project managers pay more when they include accessories in the overall package, such as toeboards, outriggers, stairways, and guardrails.

- Rental duration: The rental cost decreases over a long period. Managers pay more to rent a mobile scaffold for a day than to rent it for a full month.

- Services: The rental cost of portable scaffolding in Dubai increases when it includes additional services such as dismantling, delivery and assembly.

Can You Use a Portable Ladder on a Scaffold?

No, you can’t see a portable ladder on a scaffold. It is not permitted under safety standards set by OSHA. A portable ladder on a scaffold creates a high centre of gravity and brings tipping hazards along with it. A ladder decreases sable platform space and may not be sacred, so it increases risks of falls or scaffold tipping. OSHA guidelines prohibit standing on ladders placed on scaffold platforms unless a qualified engineer approves this assembly. A portable scaffold has limited load capacity, and adding a ladder on the scaffold concentrates weight on a small space and exceeds the tolerance of the platform. The best way to raise height safely is with some alternative to ladders, such as scaffold extension frames or internal access ladder installation.